Directional Control Valves Working Principle Doering shop air (pneumatic) pilot operated valves provide a simple solution to controlling mediums such as HYDRAULIC oil, NITROGEN or other fluids or gases. We offer many pilot to working port ratios. This allows the use of standard shop air pilot (50-150 psi). Working port pressure ratings are available up to 5,000 psi on some valves.

Pneumatic Processing parker.com

Manual Overrides Comatrol. Declutchable Manual Override for Series 79 Actuator. The declutchable manual override for the series 79P is a gear box for manually operating the 79 series pneumatic actuator from Asahi/America. The gear box itself mounts between the pneumatic actuator and valve. The featured declutch mechanism is used for separating the actuator drive from the, The basics of pneumatic control valves Directional valves such as Parker Hannifin's B3G-Series threeway (left) and four-way valves are often used to control pneumatic operations. Aug 08, 2002.

Doering shop air (pneumatic) pilot operated valves provide a simple solution to controlling mediums such as HYDRAULIC oil, NITROGEN or other fluids or gases. We offer many pilot to working port ratios. This allows the use of standard shop air pilot (50-150 psi). Working port pressure ratings are available up to 5,000 psi on some valves. Description. V60 Series pneumatic in-line directional control valves are available for 2-way, 3-way or 4-way operation. These pneumatic valves can be operated by air pilot or solenoid pilot with low power consumption 24VDC solenoids.

– Manual override, optional – Electrical connection as individual or central connection, see RE 23178 and RE 08010 – Switching time adjustment, optional – Pre-load valve in channel P of main valve, optional – Stroke adjustment of main spool, optional – Stroke adjustment and/or end position control, optional "manual overrides. The manual overrides are “safety” features for when power is lost and the solenoid needs to be operated. 2 position valves with manual overrides, when activated, shift the valve to its energized position. Some 3 position valves come standard with a one-direction, push-pin manual override. When the manual override is

pneumatic differential spring return air operated and spring return (5/3) solenoid air operated and spring return (5/3) + + + + + manual operator on control valve (or position testor) auxiliary manual operator on solenoid valve manual operator auxiliary manual operator on solenoid valve symbol for manual operator auxiliary manual operator on 1.1.2.1 Bettis does not recommend periodic field maintenance for the M11 Manual Hydraulic Override System (pump and reservoir). 1.1.2.2 The only time the M11 Manual Hydraulic Override System should be disassembled is when either the pump or the reservoir fails to perform its manual hydraulic override …

this manual, are Engineering Technology teachers in the Birmingham Public Control of Pneumatic Energy Working energy transmitted pneumatically must be directed and under complete control at all times. If not under control, useful work will not be done and machinery or machine operators might be harmed. One of the advantages of transmitting energy pneumatically is that energy can be – Manual override, optional – Electrical connection as individual or central connection, see RE 23178 and RE 08010 – Switching time adjustment, optional – Pre-load valve in channel P of main valve, optional – Stroke adjustment of main spool, optional – Stroke adjustment and/or end position control, optional

pneumatic differential spring return air operated and spring return (5/3) solenoid air operated and spring return (5/3) + + + + + manual operator on control valve (or position testor) auxiliary manual operator on solenoid valve manual operator auxiliary manual operator on solenoid valve symbol for manual operator auxiliary manual operator on 17/10/2017В В· This video explains how the pneumatic circuit is used to operate the single acting & double acting cylinder. It uses Filter Regulator & Lubricator (F.R.L.) u...

ASCO is an innovation leader in pneumatics and motion control. Our Numatics product line has a history of technological breakthroughs. It offers a broad range of 2-, 3-, and 4-way air-piloted and solenoid-operated directional control valves with fieldbus and I/O capabilities. Declutchable Manual Override for Series 79 Actuator. The declutchable manual override for the series 79P is a gear box for manually operating the 79 series pneumatic actuator from Asahi/America. The gear box itself mounts between the pneumatic actuator and valve. The featured declutch mechanism is used for separating the actuator drive from the

pneumatic differential spring return air operated and spring return (5/3) solenoid air operated and spring return (5/3) + + + + + manual operator on control valve (or position testor) auxiliary manual operator on solenoid valve manual operator auxiliary manual operator on solenoid valve symbol for manual operator auxiliary manual operator on position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve

Description. V60 Series pneumatic in-line directional control valves are available for 2-way, 3-way or 4-way operation. These pneumatic valves can be operated by air pilot or solenoid pilot with low power consumption 24VDC solenoids. Pneumadyne offers pneumatic valves, air control valves, pneumatic switches, directional valves, and more to help you find the right air control valve for your fluid power circuitry. Our pneumatic valves have flow rates from 2.90 to 57 scfm at 125 psi, and operating pressures from 26” …

A 3-way valve has three working ports. These ports are: inlet, outlet, and exhaust (ortank). A 3-way valve not only supplies fluid to an actuator, but allows fluid to return from it as well. Figures 5 through 10 show schematic symbols for 3-way directional control valves. Solenoid/pneumatic valves, ISO 15407-1 Key features Single valve manifold VTIA Signal status display via LED Various valve functions Fittings with external hex One valve series for different flow rates Signal status display via illuminating seal Manual override Blanking plate for vacant/ expansion position Pilot valve with port pattern to ISO 15218

This course is designed specifically for millwrights, electricians, reliability technicians, supervisors and engineers who are responsible for maintaining and controlling pneumatic systems. The person maintaining air systems in today’s modern plant must know the following: The function of each pneumatic component. This includes compressors 17/10/2017 · This video explains how the pneumatic circuit is used to operate the single acting & double acting cylinder. It uses Filter Regulator & Lubricator (F.R.L.) u...

Pneumatic Directional Control Valves air or solenoid operated.

Declutch Gear Box Manual Override for Pneumatic Actuators. 31/05/2017В В· The Animation Working Principle of Pneumatic Actuator and actuated butterfly valve., 31/05/2017В В· The Animation Working Principle of Pneumatic Actuator and actuated butterfly valve..

Solenoid/pneumatic valves ISO 15407-1 Festo. Series 05 Valve Actuator Manual Override. Available for 2” - 36” (50mm - 900mm) valves. This valve actuator manual override is excellent for the safe handling of spring return actuators. During pneumatic operation, the worm of the gear unit is disengaged. Should the valve require opening or closing in the event of power loss, manual, Declutchable Manual Override for Series 79 Actuator. The declutchable manual override for the series 79P is a gear box for manually operating the 79 series pneumatic actuator from Asahi/America. The gear box itself mounts between the pneumatic actuator and valve. The featured declutch mechanism is used for separating the actuator drive from the.

How the pneumatic circuit works (single acting & double

Pipeline Shutdown Valves National Oilwell Varco. 950-PT1 Pneumatic Troubleshooting System teaches pneumatic trouble-shooting like no other product in the market today. A hands-on learning station models a real world electro-pneumatic machine with 30 faults that can be inserted into the system. Amatrol’s FaultPro allows … https://en.wikipedia.org/wiki/Solenoid_valve Doering shop air (pneumatic) pilot operated valves provide a simple solution to controlling mediums such as HYDRAULIC oil, NITROGEN or other fluids or gases. We offer many pilot to working port ratios. This allows the use of standard shop air pilot (50-150 psi). Working port pressure ratings are available up to 5,000 psi on some valves..

A 5/2-way valve has five ports and two states. They are used for instance to control double acting cylinders. 5/2-way valves can be mono-stable (1 solenoid, spring return) or bi-stable (solenoids). A pneumatic cylinder uses the pressure of a gas to perform work, specifically linear work. The word "pneumatic" comes from the Greek and refers to air, which is the least expensive and most common type of gas used in pneumatic cylinders. Air can be easily taken in and compressed to refill pneumatic systems, and does not pose the same danger as

this manual, are Engineering Technology teachers in the Birmingham Public Control of Pneumatic Energy Working energy transmitted pneumatically must be directed and under complete control at all times. If not under control, useful work will not be done and machinery or machine operators might be harmed. One of the advantages of transmitting energy pneumatically is that energy can be A 5/2-way valve has five ports and two states. They are used for instance to control double acting cylinders. 5/2-way valves can be mono-stable (1 solenoid, spring return) or bi-stable (solenoids).

Declutchable Manual Override for Series 79 Actuator. The declutchable manual override for the series 79P is a gear box for manually operating the 79 series pneumatic actuator from Asahi/America. The gear box itself mounts between the pneumatic actuator and valve. The featured declutch mechanism is used for separating the actuator drive from the 1.1.2.1 Bettis does not recommend periodic field maintenance for the M11 Manual Hydraulic Override System (pump and reservoir). 1.1.2.2 The only time the M11 Manual Hydraulic Override System should be disassembled is when either the pump or the reservoir fails to perform its manual hydraulic override …

2. The working pressure shouldn’t exceed 6 bar, that could be achieved by adjusting the pressure regulator in the air service unit to 6 bar. 3. Securely plug in pneumatic devices. 4. Keep piston rod travel free. 5. Check all connections before connecting the compressed air. 6. Do not exceed the maximum pressure. 7. Do not completely unscrew Description. V60 Series pneumatic in-line directional control valves are available for 2-way, 3-way or 4-way operation. These pneumatic valves can be operated by air pilot or solenoid pilot with low power consumption 24VDC solenoids.

pneumatic differential spring return air operated and spring return (5/3) solenoid air operated and spring return (5/3) + + + + + manual operator on control valve (or position testor) auxiliary manual operator on solenoid valve manual operator auxiliary manual operator on solenoid valve symbol for manual operator auxiliary manual operator on The basics of pneumatic control valves Directional valves such as Parker Hannifin's B3G-Series threeway (left) and four-way valves are often used to control pneumatic operations. Aug 08, 2002

of pneumatic manual override output Without 0,130PSM-B10 3 manual override Step module subbase Type Description Swivel push-in*WeightOrder code D connection Kg Subbase Г4 mm 0,040 PSB-A12 1 * For other type of connections contact technical sales Technical Sales Department Main data for Line mounted elements Doering shop air (pneumatic) pilot operated valves provide a simple solution to controlling mediums such as HYDRAULIC oil, NITROGEN or other fluids or gases. We offer many pilot to working port ratios. This allows the use of standard shop air pilot (50-150 psi). Working port pressure ratings are available up to 5,000 psi on some valves.

Modular solenoid valves and accessories that have been designed for manifold assembly, and DIN rail mounting.The valves act as a functional interface between electrical/electronic control systems and pneumatic drives.Main Features:. Available as Impulse, maintained and with or without override Electrical connections via sub-base. ASCO is an innovation leader in pneumatics and motion control. Our Numatics product line has a history of technological breakthroughs. It offers a broad range of 2-, 3-, and 4-way air-piloted and solenoid-operated directional control valves with fieldbus and I/O capabilities.

position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve Description. V60 Series pneumatic in-line directional control valves are available for 2-way, 3-way or 4-way operation. These pneumatic valves can be operated by air pilot or solenoid pilot with low power consumption 24VDC solenoids.

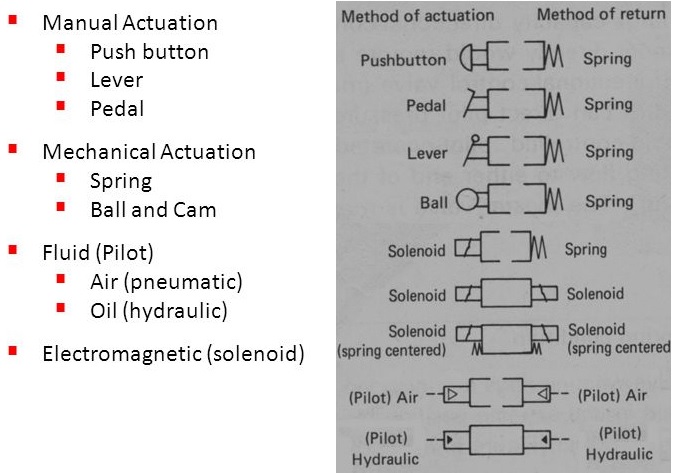

Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. Actuating methods. Manual, spring, electrical, pneumatic, and hydraulic. position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve

2. The working pressure shouldn’t exceed 6 bar, that could be achieved by adjusting the pressure regulator in the air service unit to 6 bar. 3. Securely plug in pneumatic devices. 4. Keep piston rod travel free. 5. Check all connections before connecting the compressed air. 6. Do not exceed the maximum pressure. 7. Do not completely unscrew 950-PT1 Pneumatic Troubleshooting System teaches pneumatic trouble-shooting like no other product in the market today. A hands-on learning station models a real world electro-pneumatic machine with 30 faults that can be inserted into the system. Amatrol’s FaultPro allows …

this manual, are Engineering Technology teachers in the Birmingham Public Control of Pneumatic Energy Working energy transmitted pneumatically must be directed and under complete control at all times. If not under control, useful work will not be done and machinery or machine operators might be harmed. One of the advantages of transmitting energy pneumatically is that energy can be 1.1.2.1 Bettis does not recommend periodic field maintenance for the M11 Manual Hydraulic Override System (pump and reservoir). 1.1.2.2 The only time the M11 Manual Hydraulic Override System should be disassembled is when either the pump or the reservoir fails to perform its manual hydraulic override …

COMPONENTS OF HYDRAULIC AND PNEUMATIC SYSTEM

Pneumatic Solenoid/Pilot-Operated Control Valves RS. 30/04/2015 · Interfaces between a double acting or spring return pneumatic actuator and a valve (eg. ball valve or butterfly valve). Allows the user to manually operate the valve. For more information visit, 2. The working pressure shouldn’t exceed 6 bar, that could be achieved by adjusting the pressure regulator in the air service unit to 6 bar. 3. Securely plug in pneumatic devices. 4. Keep piston rod travel free. 5. Check all connections before connecting the compressed air. 6. Do not exceed the maximum pressure. 7. Do not completely unscrew.

Pneumatic Valves Numatics - Directional Control ISO

Working Principle of Pneumatic Actuator and actuated. This course is designed specifically for millwrights, electricians, reliability technicians, supervisors and engineers who are responsible for maintaining and controlling pneumatic systems. The person maintaining air systems in today’s modern plant must know the following: The function of each pneumatic component. This includes compressors, Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. Actuating methods. Manual, spring, electrical, pneumatic, and hydraulic..

In hydraulics, liquids are not. Other two distinct differences are given below. The pneumatic systems have two main features: Pneumatic systems use compressed gas such as air or nitrogen to perform work processes. Pneumatic systems are open systems, exhausting the compressed air to atmosphere after use. The hydraulic systems also have two main 2. The working pressure shouldn’t exceed 6 bar, that could be achieved by adjusting the pressure regulator in the air service unit to 6 bar. 3. Securely plug in pneumatic devices. 4. Keep piston rod travel free. 5. Check all connections before connecting the compressed air. 6. Do not exceed the maximum pressure. 7. Do not completely unscrew

with manual override by impulse 81 513 103 4/2 monostable Г 4 ext. Solenoid valve with manual override by impulse 81 513 203 Valves and solenoids valves assembled Function Sub-base with push-in connection for semi-rigid tubing (NFE 49100) Version Voltage 24 VDC (+10% -15%) Part numbers Symbol Contact us for Other versions Characteristics Declutchable Manual Override for Series 79 Actuator. The declutchable manual override for the series 79P is a gear box for manually operating the 79 series pneumatic actuator from Asahi/America. The gear box itself mounts between the pneumatic actuator and valve. The featured declutch mechanism is used for separating the actuator drive from the

of pneumatic manual override output Without 0,130PSM-B10 3 manual override Step module subbase Type Description Swivel push-in*WeightOrder code D connection Kg Subbase Г4 mm 0,040 PSB-A12 1 * For other type of connections contact technical sales Technical Sales Department Main data for Line mounted elements Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. Actuating methods. Manual, spring, electrical, pneumatic, and hydraulic.

Manual overrides are available for all Sun two position solenoid valves. (An exception is model DNDC 3-position, 4-way car-tridge which is not available with manual overrides.) 760 solenoid/coil assemblies come equipped with a manual override button as a standard feature. 77* solenoid/coil assemblies are available with the following options: No manual override Manual override pin Twist/Lock position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve

with manual override by impulse 81 513 103 4/2 monostable Г 4 ext. Solenoid valve with manual override by impulse 81 513 203 Valves and solenoids valves assembled Function Sub-base with push-in connection for semi-rigid tubing (NFE 49100) Version Voltage 24 VDC (+10% -15%) Part numbers Symbol Contact us for Other versions Characteristics Directional control valves: 5/2-way single solenoid valve, actuated by solenoid and pneumatic piloting, air spring return, manual override

this manual, are Engineering Technology teachers in the Birmingham Public Control of Pneumatic Energy Working energy transmitted pneumatically must be directed and under complete control at all times. If not under control, useful work will not be done and machinery or machine operators might be harmed. One of the advantages of transmitting energy pneumatically is that energy can be Doering shop air (pneumatic) pilot operated valves provide a simple solution to controlling mediums such as HYDRAULIC oil, NITROGEN or other fluids or gases. We offer many pilot to working port ratios. This allows the use of standard shop air pilot (50-150 psi). Working port pressure ratings are available up to 5,000 psi on some valves.

actuation, manual, mechanical, solenoid, pilot & pneumatic. Four-way valve comes with two or three position. One should note that the graphical symbol of the valve shows only one tank port even though the physical design may have two as it is only concerned with the function. 3.1. Three positions, Four way valve: These type of DCV consists of three In hydraulics, liquids are not. Other two distinct differences are given below. The pneumatic systems have two main features: Pneumatic systems use compressed gas such as air or nitrogen to perform work processes. Pneumatic systems are open systems, exhausting the compressed air to atmosphere after use. The hydraulic systems also have two main

position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve Modular solenoid valves and accessories that have been designed for manifold assembly, and DIN rail mounting.The valves act as a functional interface between electrical/electronic control systems and pneumatic drives.Main Features:. Available as Impulse, maintained and with or without override Electrical connections via sub-base.

actuation, manual, mechanical, solenoid, pilot & pneumatic. Four-way valve comes with two or three position. One should note that the graphical symbol of the valve shows only one tank port even though the physical design may have two as it is only concerned with the function. 3.1. Three positions, Four way valve: These type of DCV consists of three 950-PT1 Pneumatic Troubleshooting System teaches pneumatic trouble-shooting like no other product in the market today. A hands-on learning station models a real world electro-pneumatic machine with 30 faults that can be inserted into the system. Amatrol’s FaultPro allows …

950-PT1 Pneumatic Troubleshooting System teaches pneumatic trouble-shooting like no other product in the market today. A hands-on learning station models a real world electro-pneumatic machine with 30 faults that can be inserted into the system. Amatrol’s FaultPro allows … Pneumatic Valves; Sorting through pneumatic directional control valves. A staff report A traditional, digital, pneumatic directional control valve consists of a body with external ports that lead to internal flow passages. One or more elements inside the valve move to open or …

Pneumatic Processing parker.com

Pneumatic Valves Pneumatic Directional Air Control. Solenoid Valve and Common Pneumatic System Symbols. Understanding ANSI / ISO Schematic Symbols for fluid power and pneumatic components are used to identify and graphically denote the function and operation of piped control systems., manual override 81 519 632 3/2 NC With maintained manual override 81 519 332 3/2 NC With manual override by impulse 1 8 0.8 25 0.3 5 15 5 107-10 +50 l 100 % ED F 35 l – IP 65 MH 15085 Function Version 15x15 mm footprint according to CNOMO E 06-36-120N bar mm Nl/min ms °C IEC 85 IEC 529 IEC 529 Miniature solenoid valves for direct current.

M11 Manual Hydraulic Override System emerson.com. Pneumatic Valves; Sorting through pneumatic directional control valves. A staff report A traditional, digital, pneumatic directional control valve consists of a body with external ports that lead to internal flow passages. One or more elements inside the valve move to open or …, Modular solenoid valves and accessories that have been designed for manifold assembly, and DIN rail mounting.The valves act as a functional interface between electrical/electronic control systems and pneumatic drives.Main Features:. Available as Impulse, maintained and with or without override Electrical connections via sub-base..

Pneumatic Solenoid/Pilot-Operated Control Valves RS

COMPONENTS OF HYDRAULIC AND PNEUMATIC SYSTEM. A 3-way valve has three working ports. These ports are: inlet, outlet, and exhaust (ortank). A 3-way valve not only supplies fluid to an actuator, but allows fluid to return from it as well. Figures 5 through 10 show schematic symbols for 3-way directional control valves. https://en.m.wikipedia.org/wiki/Voltmeter position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve.

A 3-way valve has three working ports. These ports are: inlet, outlet, and exhaust (ortank). A 3-way valve not only supplies fluid to an actuator, but allows fluid to return from it as well. Figures 5 through 10 show schematic symbols for 3-way directional control valves. Modular solenoid valves and accessories that have been designed for manifold assembly, and DIN rail mounting.The valves act as a functional interface between electrical/electronic control systems and pneumatic drives.Main Features:. Available as Impulse, maintained and with or without override Electrical connections via sub-base.

– Manual override, optional – Electrical connection as individual or central connection, see RE 23178 and RE 08010 – Switching time adjustment, optional – Pre-load valve in channel P of main valve, optional – Stroke adjustment of main spool, optional – Stroke adjustment and/or end position control, optional Declutchable Manual Override for Series 79 Actuator. The declutchable manual override for the series 79P is a gear box for manually operating the 79 series pneumatic actuator from Asahi/America. The gear box itself mounts between the pneumatic actuator and valve. The featured declutch mechanism is used for separating the actuator drive from the

Solenoid/pneumatic valves, ISO 15407-1 Key features Single valve manifold VTIA Signal status display via LED Various valve functions Fittings with external hex One valve series for different flow rates Signal status display via illuminating seal Manual override Blanking plate for vacant/ expansion position Pilot valve with port pattern to ISO 15218 Manual overrides are available for all Sun two position solenoid valves. (An exception is model DNDC 3-position, 4-way car-tridge which is not available with manual overrides.) 760 solenoid/coil assemblies come equipped with a manual override button as a standard feature. 77* solenoid/coil assemblies are available with the following options: No manual override Manual override pin Twist/Lock

if not required. Manual Override Options CETOP 3 piloted models only, omit if not required. Blank - Plain override in solenoid ends only H - Waterproof override in solenoid ends only H2- Waterproof override in both ends of single solenoid P2- Plain override in both ends of single solenoid Y - Lockable manual override in solenoid ends only (DC models only) Z - No override in either end Fast of pneumatic manual override output Without 0,130PSM-B10 3 manual override Step module subbase Type Description Swivel push-in*WeightOrder code D connection Kg Subbase Г4 mm 0,040 PSB-A12 1 * For other type of connections contact technical sales Technical Sales Department Main data for Line mounted elements

Versa Valves, 70 Years and Counting: A Reason to Celebrate Read more Versa's AR II - 316 Stainless Steel Filter Regulator Read more Pneumatic/Hydraulic Pressure Sensor Read more The Versa E-Stop valve is designed for pneumatic systems that require an emergency stop function. Pneumatic Emergency Stop: Manual Button Read more Highly accurate pressure regulation in the harshest environments. "manual overrides. The manual overrides are “safety” features for when power is lost and the solenoid needs to be operated. 2 position valves with manual overrides, when activated, shift the valve to its energized position. Some 3 position valves come standard with a one-direction, push-pin manual override. When the manual override is

position (NOT function) Quick coupling with mechanically opening non-return valves, connected 4/3-way valve, mid position working lines exhausted Equation Function table Designation Identity Or And Implication Memory DIN EN 60617-7 electrical Representation to Representation to ISO 1219/1 pneumatic t expired t expired Pressure relief valve this manual, are Engineering Technology teachers in the Birmingham Public Control of Pneumatic Energy Working energy transmitted pneumatically must be directed and under complete control at all times. If not under control, useful work will not be done and machinery or machine operators might be harmed. One of the advantages of transmitting energy pneumatically is that energy can be

A pneumatic cylinder uses the pressure of a gas to perform work, specifically linear work. The word "pneumatic" comes from the Greek and refers to air, which is the least expensive and most common type of gas used in pneumatic cylinders. Air can be easily taken in and compressed to refill pneumatic systems, and does not pose the same danger as 2 Manual override 3 Suitable for plug sockets to EN 175301-803, form C: MSSD-EB or KMEB-… 4 Manual override tool (accessory) AHB-ME-x 5 Port for external pilot air on S types 1) The seal must not be turned! Semi in-line valve for manifold PRS-ME 1 Solenoid coil can be rotated 180°1) 2 Manual override 3 Suitable for plug sockets to EN 175301

1.1.2.1 Bettis does not recommend periodic field maintenance for the M11 Manual Hydraulic Override System (pump and reservoir). 1.1.2.2 The only time the M11 Manual Hydraulic Override System should be disassembled is when either the pump or the reservoir fails to perform its manual hydraulic override … Doering shop air (pneumatic) pilot operated valves provide a simple solution to controlling mediums such as HYDRAULIC oil, NITROGEN or other fluids or gases. We offer many pilot to working port ratios. This allows the use of standard shop air pilot (50-150 psi). Working port pressure ratings are available up to 5,000 psi on some valves.

if not required. Manual Override Options CETOP 3 piloted models only, omit if not required. Blank - Plain override in solenoid ends only H - Waterproof override in solenoid ends only H2- Waterproof override in both ends of single solenoid P2- Plain override in both ends of single solenoid Y - Lockable manual override in solenoid ends only (DC models only) Z - No override in either end Fast Pneumatic Valves; Sorting through pneumatic directional control valves. A staff report A traditional, digital, pneumatic directional control valve consists of a body with external ports that lead to internal flow passages. One or more elements inside the valve move to open or …

17/10/2017В В· This video explains how the pneumatic circuit is used to operate the single acting & double acting cylinder. It uses Filter Regulator & Lubricator (F.R.L.) u... A 3-way valve has three working ports. These ports are: inlet, outlet, and exhaust (ortank). A 3-way valve not only supplies fluid to an actuator, but allows fluid to return from it as well. Figures 5 through 10 show schematic symbols for 3-way directional control valves.

This course is designed specifically for millwrights, electricians, reliability technicians, supervisors and engineers who are responsible for maintaining and controlling pneumatic systems. The person maintaining air systems in today’s modern plant must know the following: The function of each pneumatic component. This includes compressors Series 05 Valve Actuator Manual Override. Available for 2” - 36” (50mm - 900mm) valves. This valve actuator manual override is excellent for the safe handling of spring return actuators. During pneumatic operation, the worm of the gear unit is disengaged. Should the valve require opening or closing in the event of power loss, manual