Proper Lifting Techniques for Back Safety Grainger KnowHow SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low.

Manual Material Handling & Ergonomic Management Programme

MANUAL LIFTING PROGRAM D&D Tech Systems Inc. Building. Loading, transporting, unloading parts and service vehicles – ensure decks and general work area are kept clean and dry. Lift items to be loaded properly using assistance or proper lifting device where necessary. Lay out and load in an efficient, safe manner ensuring full use of available space and properly balanced load. Secure all items in, Work-related stress can affect the development of MSDs. For example, job demands, low job control, and poor support might affect how someone goes about their job. Control the risks. Work through the following list to control hazardous manual handling risks. The Occupational Health and Safety Regulations 2017 (OHS Regulations) set out specified.

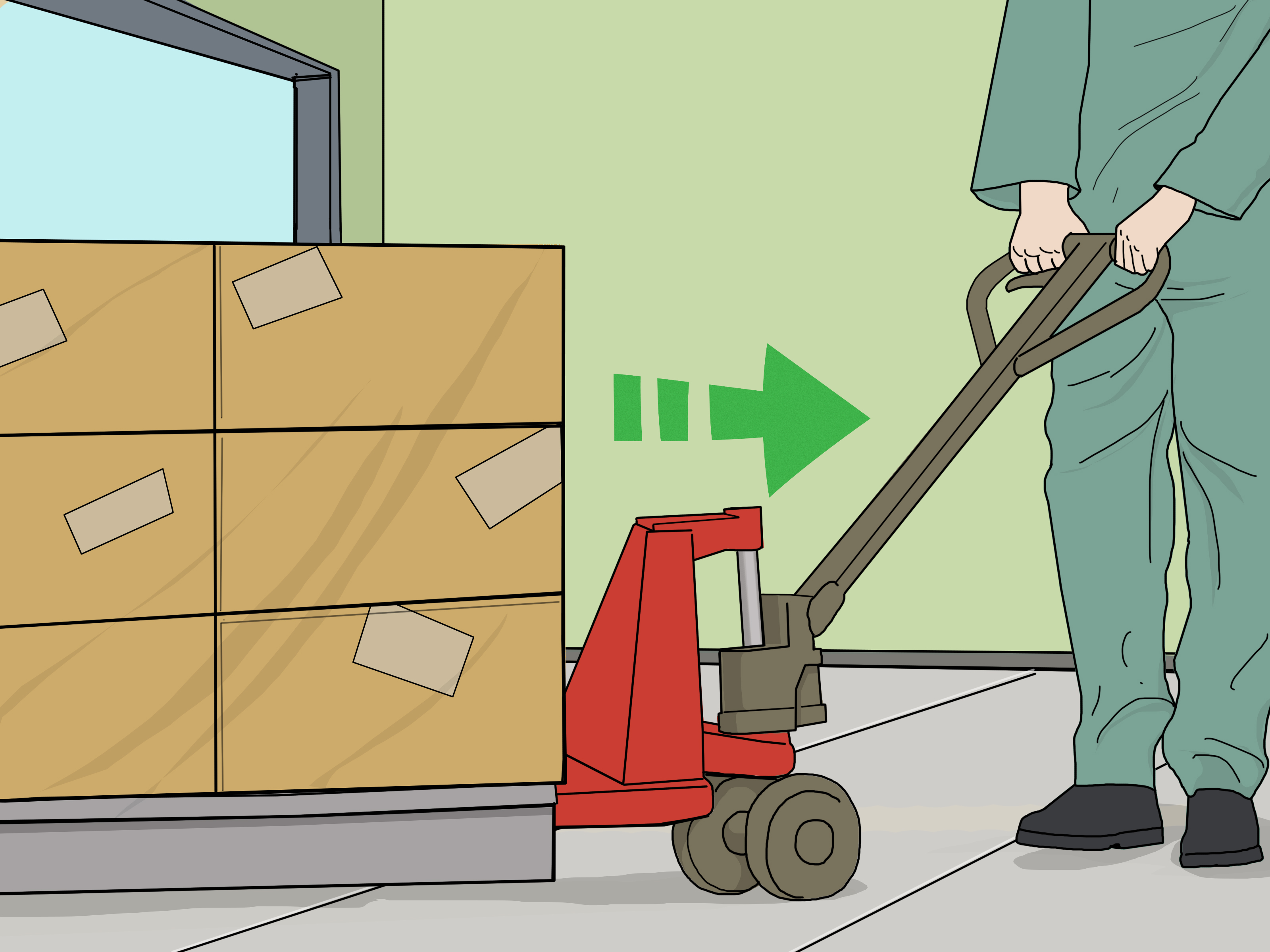

• Organise a smooth work flow – area around object, travel path and destination is clear. Signage &/or barriers may be required. • Ensure mechanical aids are available as required • Provide sufficient staff numbers • Train in safe team lifting procedures & use only when other means are not available SWA is not a regulator and cannot advise you about lifting, pulling, pushing and manual tasks in the workplace. If you need help, please contact your state or territory work health and safety authority.

Loading, transporting, unloading parts and service vehicles – ensure decks and general work area are kept clean and dry. Lift items to be loaded properly using assistance or proper lifting device where necessary. Lay out and load in an efficient, safe manner ensuring full use of available space and properly balanced load. Secure all items in RIGGING SAFE OPERATING PROCEDURES. All personnel involved with the use of rigging gear should be thoroughly instructed and trained to comply with the following practices: 1. Wire rope slings must not be used with loads that exceed the rated capacities outlined in enclosure (2) of the COMSECOND/COMTHIRDNCBINST 11200.11. Slings not included in

Use this sample to develop your own safe work procedure for using a manual metal arc welder. SWP Welder oxy-fuel gas (DOC, 141.5 KB) Use this sample to develop your own safe work procedure for using an oxy-fuel gas welder. Loading, transporting, unloading parts and service vehicles – ensure decks and general work area are kept clean and dry. Lift items to be loaded properly using assistance or proper lifting device where necessary. Lay out and load in an efficient, safe manner ensuring full use of available space and properly balanced load. Secure all items in

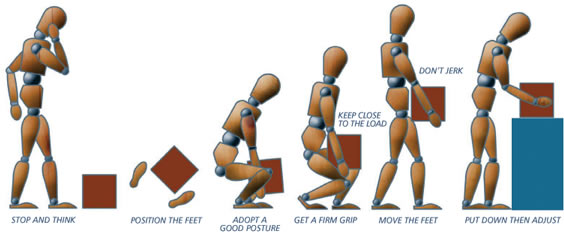

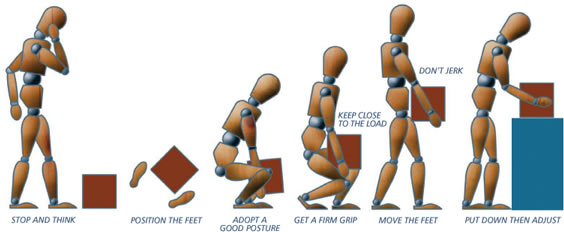

To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce … Working Procedure (COFA Manual Handling Safe Issue Date: 16/3/2011) List legislation, standards and codes of practice used in development of the SWP Work Health and Safety Act 2011 (NSW), Work Health and Safety Regulations 2011 (NSW) National Code of Practice for Manual Handling NOHSC: 2005(1990) SafeWork Australia

SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low. of the safe working practices and procedures that should be implemented within their workplaces and for the activities they undertake. 1.4. The organisation acknowledges its responsibilities under the Health and Safety at Work Act 1974, The Management of Health and Safety at Work Regulations 1999, and The Manual Handling Operations Regulations

2. Use the Manual Lifting Safe Work Practice (section III-F, SWP-1) for stationary material. 3. If vehicle is equipped with rotary light, have it operating at all times while in operation. Water Trucks: 1. Drive route and load and unload using the Manual Lifting Safe Work Practice (section III-F, SWP-1). 2. Park off main road area if possible Loading, transporting, unloading parts and service vehicles – ensure decks and general work area are kept clean and dry. Lift items to be loaded properly using assistance or proper lifting device where necessary. Lay out and load in an efficient, safe manner ensuring full use of available space and properly balanced load. Secure all items in

SWA is not a regulator and cannot advise you about lifting, pulling, pushing and manual tasks in the workplace. If you need help, please contact your state or territory work health and safety authority. 12/12/2019 · Subscribe to information about: Australian Work Health and Safety Strategy Chemical exposure standards Disease, injury and behavioural issues Diving Hazardous substances and dangerous goods Hazards and safety issues Information Publication Scheme (IPS) Media releases National Return to Work Strategy National Safe Work Month QuadWatch Research

5C Safe Work Procedure - Working in the Sun 5D Safe Work Procedure - Working with Chain Saws 5E Safe Work Procedure - Supplied Breathing Air for Abrasive Blasting 5F Safe Work Procedure - Snow Removal at Ferry Terminals 5G Safe Work Procedure - Lock Out / Tagout Procedure 5H Safe Work Procedure - Powered Aerial Work Platforms 6A Hazard Concern To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce …

SAFE WORK PRACTICE TITLE Manual Lifting And Carrying GENERAL Protecting workers from injuries associated with material lifting and carrying. APPLICATION Most lifting accidents are due to improper lifting methods. All manual lifting should be planned and safe lifting procedures followed. PROTECTIVE MECHANISMS Permit system. Safe work procedure SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low.

This ACOP serves as a reference standard of acceptable practices for manual handling operations in Singapore. It provides users, employers, manufacturers and suppliers information on ergonomics principles for manual handling work that reduce the risk of MSD injuries and disorders. Bureau of Labor Statistics Nonfatal Occupational Injuries and Illnesses Case and Demographic Characteristics for Work-related Injuries and Illnesses Involving Days Away From Work Calendar Year 2017 Survey Results. Applications Manual for the Revised NIOSH Lifting Equation. Back Injuries – Nation’s #1 Workplace Safety Problem

Safety Management Code 09 Manual Handling. Working Procedure (COFA Manual Handling Safe Issue Date: 16/3/2011) List legislation, standards and codes of practice used in development of the SWP Work Health and Safety Act 2011 (NSW), Work Health and Safety Regulations 2011 (NSW) National Code of Practice for Manual Handling NOHSC: 2005(1990) SafeWork Australia, Company Name SAFE WORK PRACTICE MANUAL LIFTING SPECIAL EQUIPMENT REQUIRED Back support where continuous heavy lifting is required. INTRODUCTION Anyone may be involved in manually lifting objects while at work or at home. Whether lifting is an everyday job or an occasional task, lifting improperly can cause serious injury regardless of the weight of the object or the physical condition of ….

PRO-4.5-0001-1-06 Lifting Operations BP

Safety Management Code 09 Manual Handling. Use this sample to develop your own safe work procedure for using a manual metal arc welder. SWP Welder oxy-fuel gas (DOC, 141.5 KB) Use this sample to develop your own safe work procedure for using an oxy-fuel gas welder., Working Procedure (COFA Manual Handling Safe Issue Date: 16/3/2011) List legislation, standards and codes of practice used in development of the SWP Work Health and Safety Act 2011 (NSW), Work Health and Safety Regulations 2011 (NSW) National Code of Practice for Manual Handling NOHSC: 2005(1990) SafeWork Australia.

Safe Work Procedures BC Municipal Safety Association. • Provision of a safe place of work for all personnel during lifting operations. The lifting plan should include a set of written safe work procedures. The occupier of a worksite has to implement a permit-to-work as specified in Part III of the WSH, The purpose of this procedure is to ensure that all operators can safely and effectively use the Genie Superlift Contractor material handling lift. 2 Introduction The Genie Superlift Contractor is a manual material handling lift designed to vertically elevate loads up to 18’ in the air. Given the potential hazards associated with material.

Safe work method statement dpi.nsw.gov.au

Lifting pushing pulling Canadian Centre for. of the safe working practices and procedures that should be implemented within their workplaces and for the activities they undertake. 1.4. The organisation acknowledges its responsibilities under the Health and Safety at Work Act 1974, The Management of Health and Safety at Work Regulations 1999, and The Manual Handling Operations Regulations heatlh and safety risks associated with manual handling for all employees, contractors and other persons. This procedure applies to all Namaqua Engineering Project personnel where manual handling is involved. 2. DEFINITIONS Ergonomics means, adapting work factors to, as far as is reasonably practicable, suit the.

RIGGING SAFE OPERATING PROCEDURES. All personnel involved with the use of rigging gear should be thoroughly instructed and trained to comply with the following practices: 1. Wire rope slings must not be used with loads that exceed the rated capacities outlined in enclosure (2) of the COMSECOND/COMTHIRDNCBINST 11200.11. Slings not included in This ACOP serves as a reference standard of acceptable practices for manual handling operations in Singapore. It provides users, employers, manufacturers and suppliers information on ergonomics principles for manual handling work that reduce the risk of MSD injuries and disorders.

This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5 -0001 Control of Work, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1. Working Procedure (COFA Manual Handling Safe Issue Date: 16/3/2011) List legislation, standards and codes of practice used in development of the SWP Work Health and Safety Act 2011 (NSW), Work Health and Safety Regulations 2011 (NSW) National Code of Practice for Manual Handling NOHSC: 2005(1990) SafeWork Australia

Bureau of Labor Statistics Nonfatal Occupational Injuries and Illnesses Case and Demographic Characteristics for Work-related Injuries and Illnesses Involving Days Away From Work Calendar Year 2017 Survey Results. Applications Manual for the Revised NIOSH Lifting Equation. Back Injuries – Nation’s #1 Workplace Safety Problem 5C Safe Work Procedure - Working in the Sun 5D Safe Work Procedure - Working with Chain Saws 5E Safe Work Procedure - Supplied Breathing Air for Abrasive Blasting 5F Safe Work Procedure - Snow Removal at Ferry Terminals 5G Safe Work Procedure - Lock Out / Tagout Procedure 5H Safe Work Procedure - Powered Aerial Work Platforms 6A Hazard Concern

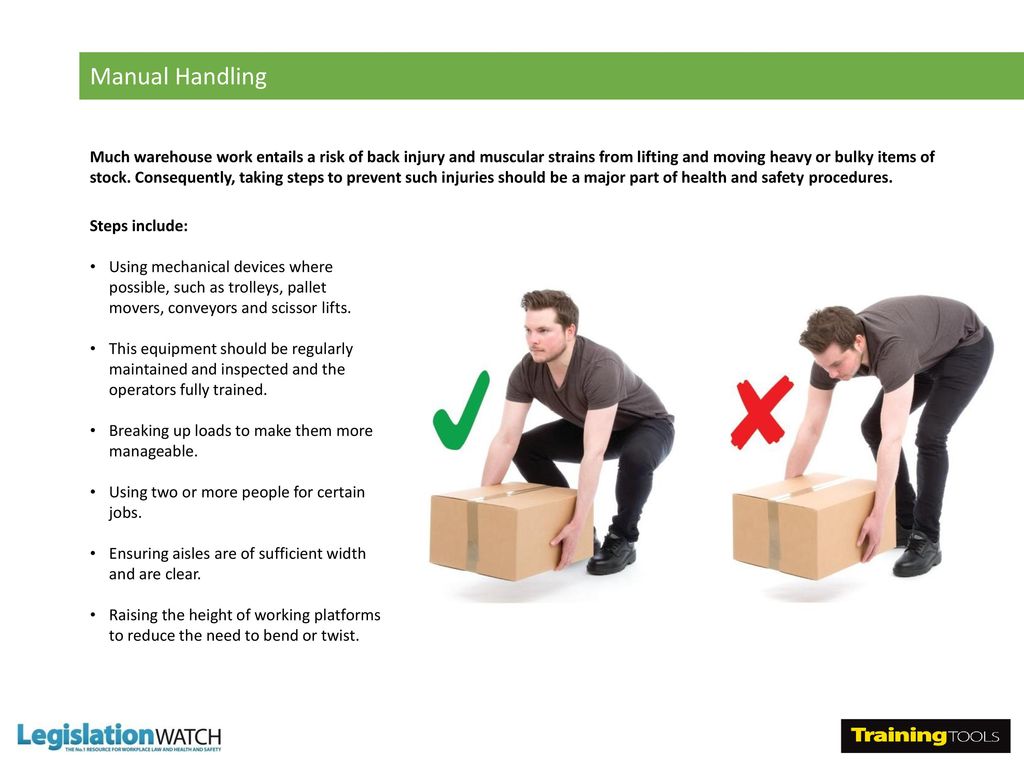

This ACOP serves as a reference standard of acceptable practices for manual handling operations in Singapore. It provides users, employers, manufacturers and suppliers information on ergonomics principles for manual handling work that reduce the risk of MSD injuries and disorders. Safe Lifting Procedures. a) Squat keeping feet shoulder width apart. b) Keep your back straight; bend your knees. c) Grasp the object firmly; be sure your grip won’t slip. d) Lift with your legs – slowly straighten them; after your legs are straight, bring your back to the vertical position. e) Hold the object close to your body.

12/12/2019 · Subscribe to information about: Australian Work Health and Safety Strategy Chemical exposure standards Disease, injury and behavioural issues Diving Hazardous substances and dangerous goods Hazards and safety issues Information Publication Scheme (IPS) Media releases National Return to Work Strategy National Safe Work Month QuadWatch Research MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 1 of 13 1. PURPOSE D&D Tech Systems, Inc. is committed to providing a safe and healthy working

RIGGING SAFE OPERATING PROCEDURES. All personnel involved with the use of rigging gear should be thoroughly instructed and trained to comply with the following practices: 1. Wire rope slings must not be used with loads that exceed the rated capacities outlined in enclosure (2) of the COMSECOND/COMTHIRDNCBINST 11200.11. Slings not included in SAFE WORK PRACTICE TITLE Manual Lifting And Carrying GENERAL Protecting workers from injuries associated with material lifting and carrying. APPLICATION Most lifting accidents are due to improper lifting methods. All manual lifting should be planned and safe lifting procedures followed. PROTECTIVE MECHANISMS Permit system. Safe work procedure

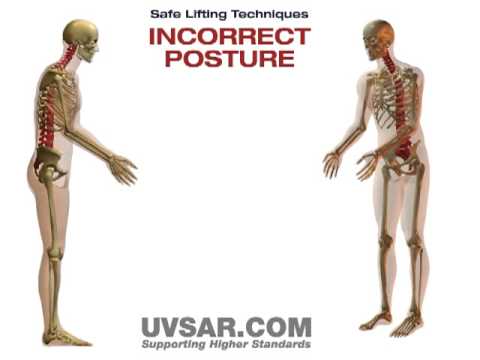

However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may Work-related stress can affect the development of MSDs. For example, job demands, low job control, and poor support might affect how someone goes about their job. Control the risks. Work through the following list to control hazardous manual handling risks. The Occupational Health and Safety Regulations 2017 (OHS Regulations) set out specified

This procedure outlines safe work practices for qualified employees who work on or near cranes or carry-deck cranes. The procedure will cover safe rigging and lifting practices, working around high voltage electricity, inspections, lift plans, personnel platforms, and worker requirements. 3 Responsibilities SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low.

HLTHSE204D Follow safe manual handling practices ISC upgrade changes to remove references to old OHS legislation and replace with references to new WHS legislation. No change to competency outcome. Unit Descriptor Descriptor This unit is concerned with the workers ability to carry out their work in a safe manner within the health care environment STANDARD OPERATING PROCEDURE Manual Handling Workplaces where hazardous manual tasks take place have an obligation to ensure the health and safety of their staff. Personnel are not expected to perform excessive physical work as technology has improved & …

To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce … STANDARD OPERATING PROCEDURE Manual Handling Workplaces where hazardous manual tasks take place have an obligation to ensure the health and safety of their staff. Personnel are not expected to perform excessive physical work as technology has improved & …

5C Safe Work Procedure - Working in the Sun 5D Safe Work Procedure - Working with Chain Saws 5E Safe Work Procedure - Supplied Breathing Air for Abrasive Blasting 5F Safe Work Procedure - Snow Removal at Ferry Terminals 5G Safe Work Procedure - Lock Out / Tagout Procedure 5H Safe Work Procedure - Powered Aerial Work Platforms 6A Hazard Concern Depending on these factors, an object that is safe to lift at one time can cause back problems another time. NIOSH has a lifting equation (discussed in the above-referenced Applications Manual) for calculating a recommended weight limit for one person under different conditions. The lifting equation establishes a maximum load of 51 pounds

knowledgeable citizens of the global community. 3. Provide a collegiate experience through instructional and support services that create a stimulating, caring, and supportive learner-centered environment in which students are encouraged to achieve the educational goals established by the university. 4. Promote a learning and working environment by providing new technologies, methodologies Mgts3606 global mobility handbook Nyirripi Global Mobility Guide 201 edition. Aerial view of Pennsylvania Avenue and the US Capitol (this page). Students at the Tempietto in Kogan Plaza, at George Washington University (opposite page). Page 9 Global Citizenship Award Discover. Discover Global Mobility Global mobility encompasses much more than traditional semester exchange, and Sydney Abroad facilitates your access to a range of

Technical Advisory for Safe Operation of Lifting Equipment

Safe work method statement dpi.nsw.gov.au. manual handling task. Safe manual handling techniques. 1 hour, tutored course 5-yearly UKRI employees who are unlikely to carry out a significant manual handling task. (mainly office based) Manual handling awareness 30 minutes, on-line. 5-yearly Others who undertake manual handling operations with UKRI equipment on UKRI sites Specific training, RIGGING SAFE OPERATING PROCEDURES. All personnel involved with the use of rigging gear should be thoroughly instructed and trained to comply with the following practices: 1. Wire rope slings must not be used with loads that exceed the rated capacities outlined in enclosure (2) of the COMSECOND/COMTHIRDNCBINST 11200.11. Slings not included in.

RIGGING SAFE OPERATING PROCEDURES tpub.com

Company Name SAFE WORK PRACTICE NLCSA. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 1 of 13 1. PURPOSE D&D Tech Systems, Inc. is committed to providing a safe and healthy working, MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 1 of 13 1. PURPOSE D&D Tech Systems, Inc. is committed to providing a safe and healthy working.

examined and tested in accordance with this Procedure. 4.8 Lifting Operators To be responsible for the correct operation of the crane in accordance with the manufacturer's instructions and within the Safe System of the work. To respond to the signals from the banksman who should be clearly identified at • Provision of a safe place of work for all personnel during lifting operations. The lifting plan should include a set of written safe work procedures. The occupier of a worksite has to implement a permit-to-work as specified in Part III of the WSH

• Organise a smooth work flow – area around object, travel path and destination is clear. Signage &/or barriers may be required. • Ensure mechanical aids are available as required • Provide sufficient staff numbers • Train in safe team lifting procedures & use only when other means are not available SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low.

Company Name SAFE WORK PRACTICE MANUAL LIFTING SPECIAL EQUIPMENT REQUIRED Back support where continuous heavy lifting is required. INTRODUCTION Anyone may be involved in manually lifting objects while at work or at home. Whether lifting is an everyday job or an occasional task, lifting improperly can cause serious injury regardless of the weight of the object or the physical condition of … • Organise a smooth work flow – area around object, travel path and destination is clear. Signage &/or barriers may be required. • Ensure mechanical aids are available as required • Provide sufficient staff numbers • Train in safe team lifting procedures & use only when other means are not available

01/11/2017 · Ensure workers are not exposed to repetitive work for long periods or work that requires a significant amount of high force. In healthcare, eliminate manual lifting of patients, except in life-threatening situations. Provide appropriate mechanical aids and equipment (eg overhead tracking, hoists, mobile hoists, wheeled equipment, slide sheets Use this sample to develop your own safe work procedure for using a manual metal arc welder. SWP Welder oxy-fuel gas (DOC, 141.5 KB) Use this sample to develop your own safe work procedure for using an oxy-fuel gas welder.

Company Name SAFE WORK PRACTICE MANUAL LIFTING SPECIAL EQUIPMENT REQUIRED Back support where continuous heavy lifting is required. INTRODUCTION Anyone may be involved in manually lifting objects while at work or at home. Whether lifting is an everyday job or an occasional task, lifting improperly can cause serious injury regardless of the weight of the object or the physical condition of … 5C Safe Work Procedure - Working in the Sun 5D Safe Work Procedure - Working with Chain Saws 5E Safe Work Procedure - Supplied Breathing Air for Abrasive Blasting 5F Safe Work Procedure - Snow Removal at Ferry Terminals 5G Safe Work Procedure - Lock Out / Tagout Procedure 5H Safe Work Procedure - Powered Aerial Work Platforms 6A Hazard Concern

5C Safe Work Procedure - Working in the Sun 5D Safe Work Procedure - Working with Chain Saws 5E Safe Work Procedure - Supplied Breathing Air for Abrasive Blasting 5F Safe Work Procedure - Snow Removal at Ferry Terminals 5G Safe Work Procedure - Lock Out / Tagout Procedure 5H Safe Work Procedure - Powered Aerial Work Platforms 6A Hazard Concern SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low.

implementing engineering controls: for example, using mechanical lifting trolleys. If a risk then remains, you must reduce it by implementing administrative controls (for example, job rotation and safe work procedures), so far as is reasonably practicable. Any remaining risk must be minimised with suitable personal protective equipment (PPE). Company Name SAFE WORK PRACTICE MANUAL LIFTING SPECIAL EQUIPMENT REQUIRED Back support where continuous heavy lifting is required. INTRODUCTION Anyone may be involved in manually lifting objects while at work or at home. Whether lifting is an everyday job or an occasional task, lifting improperly can cause serious injury regardless of the weight of the object or the physical condition of …

Work-related stress can affect the development of MSDs. For example, job demands, low job control, and poor support might affect how someone goes about their job. Control the risks. Work through the following list to control hazardous manual handling risks. The Occupational Health and Safety Regulations 2017 (OHS Regulations) set out specified 12/12/2019 · Subscribe to information about: Australian Work Health and Safety Strategy Chemical exposure standards Disease, injury and behavioural issues Diving Hazardous substances and dangerous goods Hazards and safety issues Information Publication Scheme (IPS) Media releases National Return to Work Strategy National Safe Work Month QuadWatch Research

• Provision of a safe place of work for all personnel during lifting operations. The lifting plan should include a set of written safe work procedures. The occupier of a worksite has to implement a permit-to-work as specified in Part III of the WSH implementing engineering controls: for example, using mechanical lifting trolleys. If a risk then remains, you must reduce it by implementing administrative controls (for example, job rotation and safe work procedures), so far as is reasonably practicable. Any remaining risk must be minimised with suitable personal protective equipment (PPE).

Update May 21, 2013: DO NOT USE the safe work procedure for cutting AC Pipe with a K-12 saw and water until further notice. Recently, a study was conducted in Kelowna for cutting AC Pipe with a Stanley “Chainsaw” (a bit of a misnomer). SWA is not a regulator and cannot advise you about lifting, pulling, pushing and manual tasks in the workplace. If you need help, please contact your state or territory work health and safety authority.

SWA is not a regulator and cannot advise you about lifting, pulling, pushing and manual tasks in the workplace. If you need help, please contact your state or territory work health and safety authority. Work-related stress can affect the development of MSDs. For example, job demands, low job control, and poor support might affect how someone goes about their job. Control the risks. Work through the following list to control hazardous manual handling risks. The Occupational Health and Safety Regulations 2017 (OHS Regulations) set out specified

Home SAFE Work Manitoba. However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may, This procedure outlines safe work practices for qualified employees who work on or near cranes or carry-deck cranes. The procedure will cover safe rigging and lifting practices, working around high voltage electricity, inspections, lift plans, personnel platforms, and worker requirements. 3 Responsibilities.

Manual Lifting Manual Lifting Procedures GWP Safety

Lifting pushing pulling Canadian Centre for. However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may, STANDARD OPERATING PROCEDURE Manual Handling Workplaces where hazardous manual tasks take place have an obligation to ensure the health and safety of their staff. Personnel are not expected to perform excessive physical work as technology has improved & ….

Genie Superlift SOP by Material Handling Lift. The purpose of this procedure is to ensure that all operators can safely and effectively use the Genie Superlift Contractor material handling lift. 2 Introduction The Genie Superlift Contractor is a manual material handling lift designed to vertically elevate loads up to 18’ in the air. Given the potential hazards associated with material, Safe Lifting Procedures. a) Squat keeping feet shoulder width apart. b) Keep your back straight; bend your knees. c) Grasp the object firmly; be sure your grip won’t slip. d) Lift with your legs – slowly straighten them; after your legs are straight, bring your back to the vertical position. e) Hold the object close to your body..

Safe work method statement dpi.nsw.gov.au

Manual Lifting Manual Lifting Procedures GWP Safety. Bureau of Labor Statistics Nonfatal Occupational Injuries and Illnesses Case and Demographic Characteristics for Work-related Injuries and Illnesses Involving Days Away From Work Calendar Year 2017 Survey Results. Applications Manual for the Revised NIOSH Lifting Equation. Back Injuries – Nation’s #1 Workplace Safety Problem Codes of Practice relating to lifting procedures. The following HSE publications can be used as guidance material relating to safety issues surrounding lifting procedures: L113, ‘Lifting Operations and Lifting Equipment Regulations 1998: Safe use of Lifting Equipment. Approved Code of Practice and Guidance’, HSE Legislation Series..

SAFE WORK PRACTICE TITLE Manual Lifting And Carrying GENERAL Protecting workers from injuries associated with material lifting and carrying. APPLICATION Most lifting accidents are due to improper lifting methods. All manual lifting should be planned and safe lifting procedures followed. PROTECTIVE MECHANISMS Permit system. Safe work procedure MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 1 of 13 1. PURPOSE D&D Tech Systems, Inc. is committed to providing a safe and healthy working

This ACOP serves as a reference standard of acceptable practices for manual handling operations in Singapore. It provides users, employers, manufacturers and suppliers information on ergonomics principles for manual handling work that reduce the risk of MSD injuries and disorders. of the safe working practices and procedures that should be implemented within their workplaces and for the activities they undertake. 1.4. The organisation acknowledges its responsibilities under the Health and Safety at Work Act 1974, The Management of Health and Safety at Work Regulations 1999, and The Manual Handling Operations Regulations

This ACOP serves as a reference standard of acceptable practices for manual handling operations in Singapore. It provides users, employers, manufacturers and suppliers information on ergonomics principles for manual handling work that reduce the risk of MSD injuries and disorders. the requirements will be specified in local procedures, safe work instructions, manuals, handbooks or specific standards. 3. Definitions Competent Person : A person who, through past experience, training or qualification, has demonstrated capability in performing a particular task. There are various levels of what is deemed competent for different aspects of lifting from simple lifts or basic

• Organise a smooth work flow – area around object, travel path and destination is clear. Signage &/or barriers may be required. • Ensure mechanical aids are available as required • Provide sufficient staff numbers • Train in safe team lifting procedures & use only when other means are not available SWA is not a regulator and cannot advise you about lifting, pulling, pushing and manual tasks in the workplace. If you need help, please contact your state or territory work health and safety authority.

12/12/2019 · Subscribe to information about: Australian Work Health and Safety Strategy Chemical exposure standards Disease, injury and behavioural issues Diving Hazardous substances and dangerous goods Hazards and safety issues Information Publication Scheme (IPS) Media releases National Return to Work Strategy National Safe Work Month QuadWatch Research However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may

manual handling task. Safe manual handling techniques. 1 hour, tutored course 5-yearly UKRI employees who are unlikely to carry out a significant manual handling task. (mainly office based) Manual handling awareness 30 minutes, on-line. 5-yearly Others who undertake manual handling operations with UKRI equipment on UKRI sites Specific training However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may

SWA is not a regulator and cannot advise you about lifting, pulling, pushing and manual tasks in the workplace. If you need help, please contact your state or territory work health and safety authority. of the safe working practices and procedures that should be implemented within their workplaces and for the activities they undertake. 1.4. The organisation acknowledges its responsibilities under the Health and Safety at Work Act 1974, The Management of Health and Safety at Work Regulations 1999, and The Manual Handling Operations Regulations

the requirements will be specified in local procedures, safe work instructions, manuals, handbooks or specific standards. 3. Definitions Competent Person : A person who, through past experience, training or qualification, has demonstrated capability in performing a particular task. There are various levels of what is deemed competent for different aspects of lifting from simple lifts or basic ergonomics, recognition of hazards and injuries, procedures for reporting hazardous conditions, and methods and procedures for early reporting of injuries, job specific training on safe lifting and work practice, hazards, and controls, noted below. The order of precedence and effectiveness of hazard control for manual lifting is as follows: 1

the requirements will be specified in local procedures, safe work instructions, manuals, handbooks or specific standards. 3. Definitions Competent Person : A person who, through past experience, training or qualification, has demonstrated capability in performing a particular task. There are various levels of what is deemed competent for different aspects of lifting from simple lifts or basic 5C Safe Work Procedure - Working in the Sun 5D Safe Work Procedure - Working with Chain Saws 5E Safe Work Procedure - Supplied Breathing Air for Abrasive Blasting 5F Safe Work Procedure - Snow Removal at Ferry Terminals 5G Safe Work Procedure - Lock Out / Tagout Procedure 5H Safe Work Procedure - Powered Aerial Work Platforms 6A Hazard Concern

SAFE Work Manitoba's latest awareness campaign shows the progress that’s been made in reducing workplace injuries over the last 10 years with the help of industry-based safety programs, employers and workers. Injury rates in Manitoba are now at an all-time low. 2. Use the Manual Lifting Safe Work Practice (section III-F, SWP-1) for stationary material. 3. If vehicle is equipped with rotary light, have it operating at all times while in operation. Water Trucks: 1. Drive route and load and unload using the Manual Lifting Safe Work Practice (section III-F, SWP-1). 2. Park off main road area if possible

To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce … of the safe working practices and procedures that should be implemented within their workplaces and for the activities they undertake. 1.4. The organisation acknowledges its responsibilities under the Health and Safety at Work Act 1974, The Management of Health and Safety at Work Regulations 1999, and The Manual Handling Operations Regulations

CORNELIUS ICE MACHINE, CCM0530WH1. Order from Heritage Parts the leading online provider of OEM commercial kitchen replacement parts. Most parts ship same day. Cornelius ice machine service manual Mt Cottrell Ice Dream, Ice Frost, Ice Peak slush machine Service Manuals and diagrams. Cornelius Ice Frost for Slurpee Service Manual В· Cornelius Ice Frost. True 93" Refrigerated Pizza Prep Table, Dough mixer, Hobart Manual Slicer, Cornelius 3 Flavor Slushie Frozen Beverage Machine, Restaurant Chairs, Bar.