Welcome to the Pelonis Oil Heater Manual. This guide provides essential information for safe and efficient operation of your oil-filled radiator heater. Read it carefully to ensure optimal performance and safety.

Overview of the Pelonis Oil Heater

The Pelonis Oil Heater is a high-efficiency, oil-filled radiator designed to provide consistent and reliable heat. It features a robust construction with a steel body and permanently sealed oil for long-lasting performance. This heater is ideal for various spaces, including bedrooms, living areas, and offices, offering quiet operation and even heat distribution. With multiple heat settings and a thermostat, it allows users to customize their comfort levels. The Pelonis Oil Heater is known for its portability, safety features, and energy-saving design, making it a practical choice for homeowners seeking effective and eco-friendly heating solutions. It is engineered to deliver warmth while maintaining a safe and stable operation.

Importance of Reading the Manual

Reading the Pelonis Oil Heater manual is crucial for safe and effective operation. It provides detailed instructions on installation, usage, and maintenance to ensure optimal performance. The manual outlines essential safety precautions to prevent accidents and hazards. By understanding the heater’s features and controls, users can customize settings for comfort and energy efficiency. It also covers troubleshooting common issues, helping users resolve problems quickly. Failure to follow the manual’s guidelines may void the warranty or lead to unsafe conditions. Taking the time to read and follow the manual ensures the heater functions correctly, prolongs its lifespan, and minimizes risks, making it a vital step for all users.

Safety Precautions

Ensure safe operation by following guidelines in the Pelonis Oil Heater manual. Keep the heater away from flammable materials and water to prevent accidents and electrical hazards. Always maintain a safe distance from children and pets to avoid burns. Regularly inspect the cord and plug for damage. Never touch hot surfaces or operate the heater near open windows. Proper installation and usage as per the manual are essential to ensure safety and efficiency. Failure to comply may result in fire risks or electrical issues. Always unplug the heater when not in use or during maintenance to prevent unexpected start-ups.

General Safety Guidelines

Always follow the Pelonis Oil Heater manual’s safety guidelines to ensure safe operation. Keep the heater away from flammable materials, water, and children. Never touch hot surfaces or operate the heater near open windows. Regularly inspect the cord and plug for damage. Avoid overheating by maintaining a safe distance from combustible materials. Ensure the heater is placed on a stable, flat surface to prevent tipping. Do not use the heater in areas with poor ventilation or near explosives. Keep the heater unplugged when not in use or during maintenance. Follow all warnings and precautions outlined in the manual to minimize risks of fire or electrical hazards. Proper usage ensures safety and efficiency.

Handling the Heater Safely

Handle the Pelonis oil heater with care to ensure safe operation. Always unplug the heater before moving it or performing maintenance. Never touch hot surfaces, as they can cause burns. Keep the heater away from water and flammable materials to prevent fire hazards. Ensure the heater is placed on a stable, flat surface to avoid tipping. Maintain a safe distance from combustible materials and keep children and pets away. Avoid operating the heater in areas with poor ventilation or near open windows. Regularly inspect the cord and plug for damage. Follow all safety guidelines outlined in the manual to minimize risks of electrical hazards or accidents. Proper handling ensures the heater functions safely and efficiently.

Emergency Procedures

In case of an emergency, turn off the heater immediately and unplug it from the power source. If the heater does not turn off or shows signs of malfunction, such as unusual smells or excessive heat, stop using it and contact customer service. Avoid moving the heater while it is hot or in operation. If you notice any electrical issues, such as sparks or frayed cords, discontinue use and seek professional assistance. In the event of a fire, do not attempt to fight it with water; instead, evacuate the area and call emergency services. Always prioritize safety and follow the manufacturer’s guidelines for handling emergencies.

- Turn off the heater and unplug it if it malfunctions.

- Do not attempt to repair the heater yourself.

- Contact Pelonis customer service for assistance.

Installation and Setup

Proper installation ensures safe and efficient operation. Place the heater on a flat, stable surface away from flammable materials. Follow the manual’s setup instructions carefully.

- Ensure the heater is placed on a level surface.

- Keep it away from water and combustible materials.

Unpacking the Heater

When you receive your Pelonis oil heater, carefully unpack it to ensure no damage occurred during shipping. Inspect the unit for any visible dents, scratches, or broken parts. Make sure all accessories, such as the power cord and user manual, are included. Gently remove any protective packaging materials, taking care not to damage the heater’s surfaces. Place the heater on a flat, stable surface, away from water or combustible materials. Before plugging it in, ensure the heater is in the “0” or “OFF” position. Take a moment to familiarize yourself with the controls and ports. If any damage is found, contact customer service immediately. Proper unpacking ensures safe and efficient operation.

Choosing the Right Location

Choose a safe and stable location for your Pelonis oil heater. Ensure it is placed on a flat, hard surface away from flammable materials, water sources, and high-traffic areas. Avoid placing it on carpets, rugs, or uneven surfaces, as this could pose a fire hazard. Keep the heater at least 3 feet away from curtains, bedding, or furniture. Position it in a well-ventilated area to prevent moisture buildup. Never place the heater near water or in humid environments, such as bathrooms or basements. Keep it out of reach of children and pets to avoid accidental burns or damage. Proper placement ensures efficient heating and safety for your home.

Initial Setup and Configuration

Before first use, ensure the Pelonis oil heater is properly unpacked and placed on a flat, stable surface. Check for any damage or loose parts and ensure all components are included. Plug the heater into a grounded electrical outlet, ensuring the voltage matches the heater’s requirements. Turn the power switch to the “0” or “OFF” position during setup. Familiarize yourself with the controls, such as the power switch, temperature dial, and any digital displays. For models with digital features, refer to the manual for programming instructions. Ensure the heater is set to the correct mode for your space. Always follow the manufacturer’s guidelines for initial setup to ensure safe and efficient operation.

Operating Instructions

Master the controls, including the power switch, temperature dial, and digital displays (if applicable); Turn the heater on by switching to the desired setting and adjust the temperature for comfort. Always monitor operation to ensure safe and efficient heating.

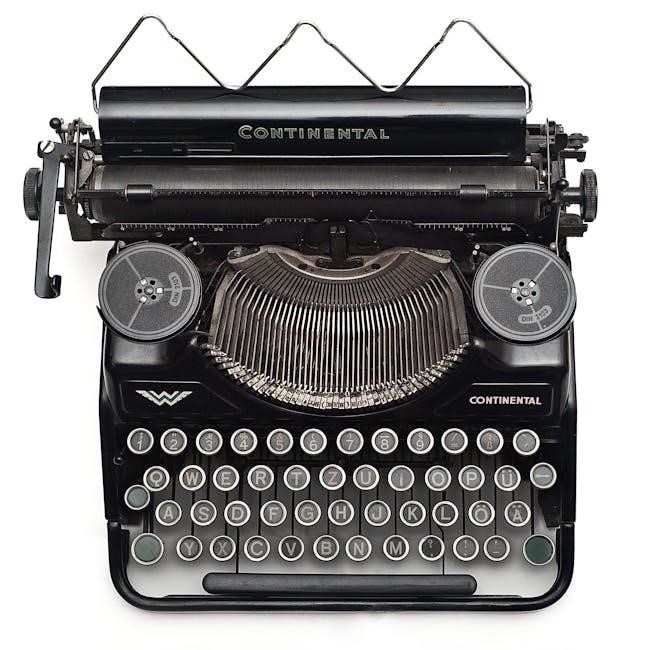

Understanding the Controls

The Pelonis oil heater features a user-friendly control panel designed for easy operation. The power switch allows you to turn the heater on and off, while the temperature dial lets you adjust the heat output to your desired level. For models with digital controls, the LCD display provides clear visibility of settings, and buttons enable precise temperature adjustments. Some units also include timers and eco-mode options for energy efficiency. Always refer to your specific model’s manual for detailed instructions on using advanced features. Familiarize yourself with the controls to ensure optimal performance and safe operation of your Pelonis oil heater.

Turning the Heater On and Off

To operate your Pelonis oil heater safely, start by ensuring it is placed on a flat, stable surface away from flammable materials. Plug the heater into a grounded electrical outlet and ensure the power switch is in the “0/OFF” position. Before turning it on, double-check that all controls are set correctly. To turn the heater on, move the power switch to the “I/ON” position. The heater will begin to warm up, and you may hear a gentle humming noise. To turn it off, switch the power to “0/OFF” and unplug the heater if not in use. Never leave the heater unattended while it is operational, especially near children or pets. Always follow these steps to ensure safe and efficient operation.

Adjusting the Temperature Settings

Adjusting the temperature on your Pelonis oil heater is straightforward. Locate the temperature control dial, typically found on the front or top of the unit. Turn the dial clockwise to increase the temperature and counterclockwise to decrease it. The heater features a built-in thermostat that automatically regulates the heat output to maintain your desired temperature. Always set the temperature between the recommended levels to avoid overheating and ensure energy efficiency. After adjusting, the heater will cycle on and off as needed. Keep the heater away from flammable materials and never leave it unattended. For precise control, refer to the indicator lights or digital display if your model includes one. Proper adjustment ensures comfort and safety while prolonging the heater’s lifespan.

Maintenance and Care

Regular maintenance ensures your Pelonis oil heater operates efficiently and safely. Clean the exterior with a soft cloth, avoiding harsh chemicals. Check for damage and store the heater properly when not in use to maintain its performance and longevity. Always unplug it before cleaning or storing. This routine care helps prevent potential issues and keeps the heater functioning optimally. By following these steps, you can enjoy consistent warmth and reliability from your Pelonis oil heater for years to come. Proper upkeep also helps in maintaining energy efficiency and ensuring safety standards are met. Keep your heater in good condition to enhance its durability and overall performance. Regular checks and timely cleaning are essential for trouble-free operation. Ensure all components are free from dust and debris to avoid any operational hindrances. This dedicated care routine will extend the lifespan of your Pelonis oil heater and ensure it continues to provide reliable service. Always refer to the manual for specific maintenance recommendations tailored to your model.

Cleaning the Heater

To maintain your Pelonis oil heater’s efficiency and safety, regular cleaning is essential. Always unplug the heater before cleaning to avoid any electrical hazards. Use a soft, dry cloth to wipe down the exterior, removing dust and debris. Avoid using harsh chemicals, abrasive cleaners, or wet cloths, as they may damage the finish or harm electrical components. For stubborn stains, a slightly damp cloth can be used, but ensure the heater is completely dry before plugging it back in. Never submerge the heater in water or expose it to excessive moisture. Cleaning the vents and grills with a soft brush can improve airflow and heat distribution. Regular cleaning helps prevent dust buildup, which can affect performance and safety. Always follow the manual’s specific cleaning guidelines to ensure optimal results. Proper maintenance ensures your heater remains efficient and safe for years to come. By keeping it clean, you enhance both its functionality and longevity. Regular cleaning is a simple yet crucial step in maintaining your Pelonis oil heater’s performance. It not only improves efficiency but also reduces the risk of potential hazards. Make cleaning a part of your routine maintenance schedule to enjoy consistent warmth and reliability from your heater. This simple care routine will extend the life of your Pelonis oil heater and keep it operating at its best. Always prioritize safety and follow the recommended cleaning procedures outlined in the manual. Your diligence in maintaining the heater will ensure it continues to provide warmth and comfort effectively. Cleaning is a key aspect of responsible heater ownership and contributes significantly to its overall performance and safety. By taking the time to clean your Pelonis oil heater regularly, you can enjoy trouble-free operation and reliable service. This straightforward maintenance task is vital for preserving the heater’s efficiency and ensuring it remains a safe and dependable source of heat for your home. Keep your Pelonis oil heater in pristine condition with regular cleaning, and it will reward you with consistent performance and longevity. Cleaning is an essential part of maintaining your Pelonis oil heater, and by doing so, you can ensure it remains a trusted and efficient heating solution for years to come.

Checking for Damage

Regularly inspect your Pelonis oil heater for any signs of damage to ensure safe and efficient operation. Check the power cord and plug for fraying, cuts, or burn marks. Examine the heater’s exterior for dents, cracks, or rust. Look for any oil leaks or stains, as these can indicate internal damage. If you notice any damage, immediately stop using the heater and unplug it. Do not attempt to repair the heater yourself, as this could void the warranty or cause safety hazards. Contact Pelonis customer service or a certified technician for professional assessment and repair. Regular inspections help prevent potential hazards and ensure the heater functions optimally. Always prioritize safety by addressing any damage promptly. If unsure about the severity of the damage, err on the side of caution and seek professional assistance. Maintaining your heater in good condition is crucial for reliability and safety. Regular checks can prevent minor issues from becoming major problems. Inspect your Pelonis oil heater before each use and after storage to ensure it remains in excellent working condition. This proactive approach protects your investment and ensures continuous safe operation. Always follow the manufacturer’s guidelines for inspecting and addressing damage. Your diligence in checking for damage will help extend the life of your heater and maintain its performance. If any damage is detected, do not hesitate to take appropriate action to avoid potential risks. Regular inspections are a simple yet effective way to keep your Pelonis oil heater in optimal shape. By taking the time to check for damage, you can enjoy peace of mind and reliable warmth from your heater. This routine maintenance step is essential for safeguarding your home and ensuring the heater’s longevity. Always make it a habit to inspect your Pelonis oil heater for damage before and after use to guarantee its safe and efficient operation. Your attention to detail will help preserve the heater’s functionality and ensure it remains a trusted source of warmth for years to come.

Storing the Heater When Not in Use

To ensure your Pelonis oil heater remains in good condition when not in use, proper storage is essential. First, unplug the heater and allow it to cool completely before moving or storing it. Clean the exterior with a soft cloth to remove any dust or debris. Store the heater in a dry, well-ventilated area away from flammable materials. Avoid basements or areas prone to moisture, as this could damage the electrical components. Keep the heater upright to prevent oil from leaking or shifting. Do not store it in extreme temperatures or near direct sunlight. Ensure the storage location is out of reach of children and pets. By following these steps, you can protect your Pelonis oil heater and ensure it remains ready for future use. Regular maintenance and proper storage will extend the life of your heater and maintain its efficiency. Always refer to the manual for specific storage recommendations. Proper storage helps preserve the heater’s functionality and ensures safety when it is used again. Make sure the heater is completely dry before storing it to prevent any damage. If storing for an extended period, check the heater periodically to ensure no issues arise. Following these guidelines will help maintain your Pelonis oil heater in optimal condition for years to come.

Troubleshooting Common Issues

If your Pelonis oil heater isn’t working, check the power connection and ensure it’s properly plugged in. Verify that the thermostat is set correctly and the unit is free from obstructions. If issues persist, consult the manual or contact customer support for assistance. Always follow safety guidelines when troubleshooting to ensure your safety and the heater’s optimal performance. Regular maintenance can help prevent many common problems. Refer to the troubleshooting section in the manual for detailed solutions. If the heater still doesn’t function, contact Pelonis customer service for further help. Proper troubleshooting ensures efficient and safe operation of your heater. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential hazards. Troubleshooting common issues promptly can extend the life of your Pelonis oil heater and maintain its efficiency. Keep the manual handy for quick reference. If the heater emits unusual noises or smells, turn it off immediately and contact support. Never attempt to fix internal components yourself. Follow the manufacturer’s guidelines for resolving issues safely and effectively. Regularly checking for damage and ensuring proper usage can prevent many common problems. If the heater is under warranty, refer to the warranty section for claim procedures. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the issue cannot be resolved, contact Pelonis customer service for professional assistance. Troubleshooting common issues is essential for maintaining the performance and longevity of your heater. Keep the manual nearby for easy troubleshooting guidance. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated; If the problem persists, consult the troubleshooting section or contact support. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are malfunctioning, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning on, check the power supply and ensure the circuit breaker hasn’t tripped. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates effectively and safely. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual noises, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating evenly, ensure proper air circulation and check for blockages. If the problem continues, consult the troubleshooting section or contact support. Troubleshooting common issues ensures optimal performance and safety. Always follow the manufacturer’s guidelines for resolving any issues. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for

Heater Not Turning On

If your Pelonis oil heater fails to turn on, first check the power supply. Ensure the heater is properly plugged into a working electrical outlet. Verify that the circuit breaker or fuse hasn’t tripped. Next, inspect the power switch to confirm it’s in the “ON” position. Check the control settings to ensure the thermostat is set correctly and the heater is not in standby mode. If the issue persists, unplug the heater, wait for 30 seconds, and plug it back in. If it still doesn’t turn on, consult the manual for further troubleshooting steps or contact Pelonis customer support. Always ensure the heater is on a flat, stable surface and free from obstructions. If the problem continues, it may indicate a malfunction requiring professional attention. Always prioritize safety and follow the manufacturer’s guidelines for troubleshooting. If the heater still doesn’t power on, contact Pelonis customer service for assistance. Regular maintenance and proper usage can help prevent such issues. Keep the manual handy for quick reference. If the heater is under warranty, refer to the warranty section for claim procedures. Troubleshooting promptly ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable

Heater Not Heating Properly

If your Pelonis oil heater isn’t heating properly, start by checking the thermostat settings. Ensure it’s set to a temperature above the room’s current temperature. Verify that the heater is plugged into a working outlet and that the circuit hasn’t tripped. Make sure the heater is on a flat, stable surface and free from obstructions. Check for any blockages in the airflow vents, as these can reduce efficiency. If the room isn’t well-insulated, the heater may struggle to maintain temperature. Reset the heater by turning it off, unplugging it, and plugging it back in after 30 seconds. If the issue persists, refer to the manual or contact Pelonis customer support for assistance. Regular maintenance and proper usage can help prevent such issues. Always follow the manufacturer’s guidelines for troubleshooting. If the heater is under warranty, refer to the warranty section for claim procedures. Troubleshooting promptly ensures your Pelonis oil heater operates safely and efficiently. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the problem continues, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always unplug the heater before inspecting or cleaning it. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly. If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s controls are unresponsive, reset the unit or refer to the manual for guidance. If the issue remains unresolved, contact Pelonis customer service. Troubleshooting common issues helps maintain the heater’s efficiency and safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater is not turning off, check the power switch and ensure it is functioning correctly; If the issue persists, consult the manual or contact support. Troubleshooting common issues ensures optimal performance and safety. Always refer to the manual for detailed troubleshooting steps. If the heater is making unusual smells, turn it off and contact customer service immediately. Troubleshooting common issues promptly can prevent further damage. Keep the manual handy for quick reference and solutions. If the heater is not heating properly, check the temperature settings and ensure the room is well-insulated. If the problem persists, consult the troubleshooting section or contact support. Troubleshooting common issues ensures your Pelonis oil heater operates safely and efficiently. Always unplug the heater before inspecting or cleaning it. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater’s thermostat is not functioning correctly, reset the unit or refer to the manual for instructions. If the problem persists, contact customer service. Troubleshooting common issues helps maintain the heater’s efficiency and longevity. Always unplug the heater before attempting any repairs. If unsure, seek professional assistance to avoid potential risks. Troubleshooting common issues ensures your Pelonis oil heater continues to provide reliable warmth and comfort. If the heater is leaking oil, turn it off immediately and contact support for assistance. Do not attempt to fix it yourself. Troubleshooting common issues promptly can prevent further damage and ensure safety. Always follow the manufacturer’s instructions for resolving any problems. If the heater’s power cord is damaged, do not use it and contact customer service for a replacement. Troubleshooting common issues ensures the heater operates safely and efficiently. Always prioritize safety when addressing any malfunctions. If the heater is not functioning after storage, refer to the manual for reset instructions or contact support. Troubleshooting common issues helps maintain the heater’s performance and longevity. Always unplug the heater before inspecting or cleaning it. Trou